Manufacturing activity picked up the pace in May, with strong demand driving backlogs to a 14-year high, according to the nation’s supply executives in the latest Manufacturing ISM Report On Business. But labor challenges, slowing supplier deliveries, and surging prices have combined to constrain an even greater growth in production.

The May PMI registered 58.7%, an increase of 1.4 percentage points from the April reading. A PMI reading above 50% indicates that the manufacturing economy is generally expanding; below 50% indicates that it is generally declining.

In other measures:

- The New Orders Index registered 63.7%, an increase of 1.4 percentage points from April, at 60 or above for the 13th straight month, and the Backlog of Orders Index reached 63.5%, up 1.5 percentage points and the highest reading since April 2004 (66.5%);

- The Prices Index registered 79.5 percent in April, a 0.2 percentage point increase and the highest level since April 2011 (82.6%), indicating higher raw materials prices for the 27th consecutive month. The ISM Business Survey Committee noted price increases in metals (all steels, steel components, aluminum and copper), corrugate, freight, electronic components, wood and some chemicals. Shortages continue in electronics components, with steels, steel-based products, electrical components, aluminum and freight added to the list this month;

- The Production Index registered 61.5%, an increase of 4.3 percentage points;

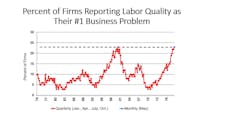

- The Employment Index registered 54.2%, a decrease of 3.1 percentage points.

- The Supplier Deliveries Index registered 62%, a 0.9 percentage point increase. Outside of last year’s hurricane period, the highest reading was registered in March 2010, when the index reached 64;

- The Inventories Index registered 50.2%, a decrease of 2.7 percentage points from April. “Suppliers were not able to maintain desired inventory expansion levels consistent with production demands for the third straight month. Wide-scale supplier lead-time extensions and freight uncertainties continue to impact inventory accounts,” said Timothy R. Fiore, CPSM, C.P.M., chair of the Institute for Supply Management (ISM) Manufacturing Business Survey Committee who issued the report.

Among the specific comments from survey respondents:

“We are currently overselling our forecast and don’t see an end to the upswing in business. We are very concerned, however, about the tariffs proposed in Section 301 and are focusing on alternatives to Chinese sourcing,” said a transportation equipment manufacturer.

“We are concerned about the strong dollar affecting our export orders as well as the steel tariffs, which are causing domestic steel prices to rise,” said a metal products fabricator.

“Sales remain strong. Lead times and direct material costs are soaring,” added a machinery manufacturer.