ACT Research addressed trends, opportunities, and challenges facing North America’s truck and trailer market during a two-day session held March 30-31 in Columbus, Indiana.

Relying on its staff of analysts and outside experts, topics included the trailer market, truck sales, and regulations that will affect the commercial vehicle market.

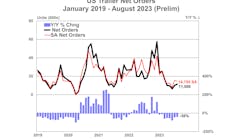

US Trailer Market: what follows the 2015 factory shipment record?

Frank Maly

The truck trailer market continues to show strength, powered by pent-up demand. However, the outlook for the year is not easily seen, pedal-to-the-metal scenario produced last year’s record year for trailer manufacturers.

ACT Research’s Frank Maly describes the current market as “murky.” Here are a few reasons why:

• Production capacity appears in balance with orders for trailers

• Regulatory issues should impact demand as they take effect.

• New production capacity is coming on stream late this year at a time when demand is softening.

• Fears of overheated market have not materialized.

• Freight demand has softened.

While Maly does not expect the industry to duplicate its performance of 2015, he said that strong demand for trailers early this year, along with continued healthy trucker profitability and an older than average fleet will combine to drive demand for dry van trailers in 2016.

“We have been producing at a high rate for a long time,” he said. “There is still some pent-up demand and some opportunity especially on the large fleet side.”

He also pointed to the backlogs that manufacturers continue to have. These backlogs help support the optimism for the expectation that 2016 will be a solid year. But the backlogs can cut both ways.

“The longer the backlogs stretch out, the greater the tendency for the orders to be cancelled,” Maly said.

Here is his outlook for trailers this year:

• Dry-freight vans. Strong demand early in 2016. Fleets are profitable, the equipment is still older than normal, and backlogs are lengthy.

• Refrigerated vans. The backlog-to-build ratio is near historic highs, but deteriorating rate fundamentals cause concern.

• Flatbeds. The oil exploration business is reeling, squelching demand for trailers. Offsetting this decline, however, are gains in the housing market. Expect aluminum trailers to grab an increased share of the flatbed market as weight, corrosion, and appearance become increasingly important to customers.

• Liquid tanks. Gains in the food and chemical segment are not enough to offset the ills in the oil patch.

• Pneumatics. These, too, are adversely affected by the woes of the oil business, and new drilling is unlikely as long as oil sells for less than $40 per barrel.

Steel Solutions for light-weighting commercial transportation

Matt Spurgeon

ArcelorMittal USA

As a rule of thumb, trailer manufacturers can reduce the tare weight of the steel components in their trailer by 10% for every grade level, Spurgeon said.

And with changes in the design of the trailer, tare weight can be trimmed even more.

He backed up those claims by reporting the results of a test project his company conducted in conjunction with Trailtech Inc, a manufacturer of light-duty trailers based in Gravelbourg, Saskatchewan, Canada.

The Trailtech light-weighting project. Spurgeon said, achieved a 35% reduction in tare weight while simultaneously reducing material costs by 29%. In addition, the project required fewer welds, less welding wire, and less time.

“Increasing by one strength level (one grade level “jump”) from 50 ksi HSLA to 60 ksi HSLA (340 MPa to 420 MPa), results in around 10% weight savings,” he said. “Two grade levels will be around 20% weight savings, and three jumps is sometimes possible, resulting in 30% weight savings.”

Regs for reefers

Todd Lutkauskas, strategic marketing manager

Thermo King

Refrigerated trailers are poised to get their share of attention in Phase 2 of the greenhouse gas proposal, but there are more regs than those on the reefer radar screen.

Lutkauskas focused on two of them—California’s Air Resource Board rules for truck-mounted refrigeration units and the Food Safety Modernization Act (FSMA).

The goal of the Air Resource Board is zero emissions, achieved by technologies such as hydrogen fuel cells. Lutkauskas said. Until then, it seeks to slash reefer unit idle time at places such as grocery stores and distribution centers.

The Food and Drug Administration, charged with enforcing the law, considers it to be “the most sweeping reform of our food safety laws in more than 70 years.” Signed into law by Obama in 2011, it aims to ensure the US food supply is safe by shifting the focus from responding to contamination to preventing it.

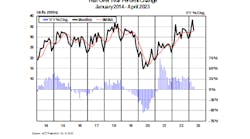

State of the CV Industry: Cooling Grips the Class 8 Market

Kenny Vieth

The good times don’t roll indefinitely. After years of strong sales, Class 8 trucks are downshifting. Kenny Vieth, ACT Research, talked about the current slowdown in his presentation on the state of the commercial vehicle market.

“This will be the first time the industry has cycled without a recession since 1995,” Vieth said. The culprit: a decline in manufacturing caused by the oil industry and the strength of dollar.

“Last year was the second-best tractor sales year in history,” Vieth said. “A drop in the fourth quarter prevented 2015 from becoming a record year.”

There is still plenty of freight to be moved, especially loads associated with the auto industry and the housing market. The auto industry, however, may have plateaued.

As a result of several years of strong production, truck manufacturers have been able to help fleets meet the nation’s need for transportation. After a major shortage in capacity coming out of the 2009 recession, freight demand exceeded the trucking industry’s ability the move it. But starting in November 2014, respondents to ACT’s survey indicated that their capacity is growing faster than freight. In 2015, the U S tractor population grew by 2%. Total fleet size has increased 11% since 2013.

Add to that the productivity increases that fleets have achieved, and the result is capacity surplus. Fleets have been able to utilize their equipment more effectively, both through tech-enabled brokering and the increased ability of private fleets to obtain backhauls. Had carriers not improved their productivity, there would have been even more demand for equipment, Vieth said.

Vieth believes freight will be up 3% this year, which bodes well for the trucking industry. “There is no substitute mode for most truck freight,” he said.

Vieth summarized his perspective this way: The domestic economy is still growing, but a strong US dollar is keeping overall economic growth spotty. High inventories will dampen freight demand.

Regulatory issues could impact demand. The mandated use of electronic logging devices will adversely affect fleet productivity, helping tighten freight capacity. In addition, greenhouse gas rules on trucks and trailers should raise the purchase price, suggesting a potential pre-buy just ahead of the implementation date. As long as fuel costs remain low, the payback period for any fuel-saving equipment mandated by the regulations will be longer.

ACT is forecasting the US market will buy 207,000 Class 8 trucks in 2016, down from 253,000 that were sold last year. Next year will be another down, with sales of 198,000 Class 8 trucks before the market again swings upward. With three straight years of sales growth, ACT expects Class 8 truck sales to again approach near-record levels in 2020.

Update on EPA/NHTSA Phase 2 Rule

So why is Phase 2 of the EPA/NHTSA greenhouse gas regulations coming, and how much will it cost? Glen Kedzie, vice-president of energy and environmental affairs for the American Trucking Associations addressed both of those questions in his ACT Research presentation.

To a certain extent, the issue is in response to political pressure. Kedzie cited polling data that indicates 76% of Americans believe climate change is happening, up from 65% five years ago. The belief is closely tied to political affiliations, with 90% of Democrats and 59% of Republicans believing in some sort of climate change. Those totally denying climate change are 28% Republicans and 3% Democrats.

Respondents blamed deforestation as the primary cause of climate change, with oil and gas consumption right behind.

All three branches of the government are involved. In 2007, Congress passed the Energy Independence & Security Act which mandated the Department of Transportation to regulate trucks for fuel efficiency. The Environmental Protection Agency derives its authority through the Clean Air Act.

The president, meanwhile, in his June 2013 Climate Action Plan, directed federal agencies to advance climate agenda including finalizing Phase 2 truck GHG/fuel efficiency standards. The Supreme Court also has weighed in, ruling in 2007 that greenhouse gases are pollutants.

Even though Phase 1 of the regulation added an estimated $6,019 to a tractor in 2014, ATA favored the regulation because the estimated 23% increase in engine efficiency would allow fleets to recover that additional cost within 24 months of buying the equipment.

However, Phase 2 is expected to add another $12,842 to the cost of a tractor when the regulation is fully implemented in 2027. And here is what ATA believes the additional cost will be for trailers:

Also speaking on the topic of greenhouse gas regulations was Sean Waters, director of product compliance with Daimler Trucks North America.

Waters said his company supports the goals of improving fuel economy and reducing greenhouse gas emissions and appreciates the effort that EPA and NHTSA have made to improve the Phase 2 proposal.

“We like a lot of the Phase 2 proposal,” he said. “It clarifies some of the ambiguities of Phase 1. But Phase 2 calls for a 24% efficiency increase by 2027.

“We have taken all the low-hanging fruit. Now it will get tough. In order to meet the 2027 standards, we will need to invent technology. But customers want proven technology.”

Some of that technology will come in the form of autonomous trucks.

“We will roll out autonomous technology soon. Benefits are already accruing. Technology is moving faster than the regulators,” he said.

But beyond looking at trucks and tractors, Waters highlighted how much greenhouse gases could be reduced and how much fuel could be saved by improvements to our highway system.

More than three billion gallons of fuel are wasted every year as a result of congestion. By contrast, the EPA estimates that its proposal will save just over a billion gallons of fuel over 10 years.

Waters said that 40% of that waste is a result of bottlenecks—simple traffic congestion. “We will do our part, designing better engines and more fuel efficient vehicles,” said, “but there are lots of other opportunities to save fuel and reduce greenhouse gases. Of all the fuel efficiency benefits we can provide our customers, they don’t get any of them when they are stuck in traffic.” ♦

How much materials will trailer OEMs buy?

ACT Research announced a new report that forecasts the amount of components and raw materials that trailer manufacturers will need to build the trailers that they are expected to manufacture.

The report includes forecasts for raw materials such as aluminum, steel, composites, hardwood and plywood. Also are included are forecasts for an array of trailer components, including doors, hardware, lighting components, axles, suspensions, brakes, wheel ends, and kingpins.

New trailer component/raw material report will be published quarterly and will include forecasts reaching out as far as five years. It will be available only to those who subscribe to the company’s Outlook report. For additional information, contact www.actresearch.net