Trailer industry faces soft demand despite October order gains

Key Highlights

- U.S. trailer net orders increased 77% MoM in October but are still 5% below last year's levels.

- Order cancellations decreased slightly, indicating some market stabilization, though fleet caution remains high.

- Backlogs hit their lowest point since mid-2020, with the industry entering mid-Q1 2026 with limited order activity.

- Production rates remain elevated to support labor and inventory needs, despite demand softening.

- Market headwinds like trade policy, high material costs, and weak freight demand continue to pressure fleet sentiment and order volumes.

U.S. trailer net orders firmed on a seasonal basis in October, climbing 77% month-over-month to 15,916 units but coming in 5% below year-ago levels, FTR reported. The sharp rebound points to “renewed fleet engagement”—and fewer cancellations—but order volumes remain far below the 10-year October average of 37,116 as operators continue to grapple with soft freight demand, weak profitability, elevated input costs, and persistent uncertainty over trade policy and macroeconomic conditions.

“The U.S. trailer market continues to experience meaningful pressure from volatile trade policy, elevated material costs, and weakening fleet sentiment,” Dan Moyer, FTR senior analyst, commercial vehicles, said. “Although a Supreme Court ruling could eliminate country-specific tariffs depending on the outcome, the main tariff cost for the trailer industry comes from the 50% Section 232 tariffs on steel, aluminum, and copper that will be unaffected.”

ACT Research reported slightly different figures. Preliminary net trailer orders in October were 5,700 units higher than September’s 11,300 level, a 51% month-to-month increase. At 17,100 units booked in October, order intake was 3% above last October’s level. Seasonal adjustment (SA) at this point in the annual order cycle lowers the monthly tally to about 12,600 units.

“Sequentially, October’s higher net order intake was expected, as it is usually one of the strongest order months in the annual cycle initiated at the end of Q3 when the industry begins opening next year’s orderboards,” said Jennifer McNealy, director CV market research and publications at ACT Research. “October’s tally brings the year-to-date net order total to 138.3k units, or 17% more net orders than were accepted through year-to-date October 2024.”

Cancellations ease

Cancellations eased to just above 5%, suggesting some stabilization, according to FTR. However, many fleets “remain cautious” and are postponing 2026 commitments until market conditions and pricing visibility improve. The modest year-over-year (y/y) decline underscores that ordering behavior is still primarily replacement-driven with limited evidence of fleets adding growth capacity.

Indeed, with the majority of 2025 “in the rearview mirror,” the U.S. trailer market remains in “stay afloat” mode, as fleets continue their wait-and-see strategy, according to this month’s issue of ACT Research’s State of the Industry: U.S. Trailers report.

“October’s trailer cancellation rate, as a percentage of backlog, was a more subdued 1.3% versus last month’s overstated 5.6%. Data continued to show elevated cancellations in reefer and tank segments,” McNealy said. “The largest level of cancels came from the tank segments, attributed to a decline in oil/gas activity, in general.”

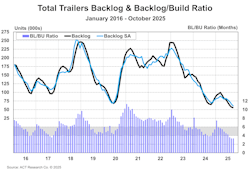

With higher build rates, lower backlogs, and two more production days in October, the industry BL/BU ratio remained at 3.3 months for the second consecutive month, ACT Research noted.

“October’s build rate and the current backlog commit the industry into mid-Q1’26,” McNealy said. “Overall, backlog remains at rock-bottom levels with the new year’s orderboards opening.”

Trailer YTD, production, backlogs

For 2025 to date, net trailer orders total 135,525 units, up 18% y/y, the FTR report stated. This increase primarily reflects backloaded demand following the November 2024 election, which pushed activity into the first quarter of 2025 that normally would have occurred in late 2024. Despite that weak start to the 2025 order cycle, the early read on the 2026 order season is “even softer.” Cumulative orders for September and October combined are down 15% y/y to 24,917 units as multiple market headwinds weigh on fleet sentiment.

Trailer production edged slightly lower in October with builds down 2% m/m but 2% higher y/y at 17,527 units. Despite the modest pullback, many OEMs have continued building at relatively elevated rates—likely “to preserve labor continuity,” support fixed-cost absorption, draw down lingering component inventories ahead of year-end, or preempt potential tariff-related cost pressures.

Backlogs declined 2% m/m and 14% y/y to 71,990 units, keeping the backlog/build ratio steady at 4.1 months—its lowest point since mid-2020, according to FTR. With production still running ahead of demand, OEMs will need to meaningfully lower build rates soon unless the 2026 order season gains further traction.

“OEMs and suppliers are adjusting to higher costs and softer demand through selective price increases, tighter cost controls, and sourcing shifts,” Moyer said. “Fleets are extending equipment life cycles, prioritizing maintenance, and limiting new capital commitments as elevated costs and policy uncertainty continue to weigh on near-term trailer demand.”

With higher build rates, lower backlogs, and two more production days in October, the industry BL/BU ratio remained at 3.3 months for the second consecutive month, per ACT Research.

“October’s build rate and the current backlog commit the industry into mid-Q1’26. Overall, backlog remains at rock-bottom levels with the new year’s orderboards opening,” McNealy said.

Speaking more broadly, McNealy added, “Looking forward, concern continues that moderating economic activity, ongoing weak for-hire carrier profitability, and ambiguous governmental policy, especially around the EPA low-NOx rule, remain as challenges to stronger trailer demand. However, pent-up demand is building, and fleets eventually will need to divert capex to trailing equipment purchases deferred over the past few years.”

About the Author

Kevin Jones

Editor

Kevin has served as editor-in-chief of Trailer/Body Builders magazine since 2017—just the third editor in the magazine’s 60 years. He is also editorial director for Endeavor Business Media’s Commercial Vehicle group, which includes FleetOwner, Bulk Transporter, Refrigerated Transporter, American Trucker, and Fleet Maintenance magazines and websites.

Working from Beaufort, S.C., Kevin has covered trucking and manufacturing for nearly 20 years. His writing and commentary about the trucking industry and, previously, business and government, has been recognized with numerous state, regional, and national journalism awards.