[The following originally was published in the December 2021 print edition of Trailer/Body Builders, focused on fabrication news.]

If you’re not getting the results you expected from investments in technology to mine your manufacturing data, there’s a good chance you’re looking at the wrong numbers—and that you’ve now about given up on all this talk of the power of “analytics.”

But you shouldn’t quit the game. To help manufacturers stay competitive in the digital age, Jon Sobel wants to keep your eye on the ball.

Sobel is the CEO and founder of Sight Machine, a plant data and analytics firm. He used his slot at FABTECH’s recent FABx Tech Talks to discuss the National Pastime, specifically the Michael Lewis book and subsequent film Moneyball.

“What I'm going to do in my time today is try to cut through some of the noise and confusion around this digital world we're all in,” Sobel began. “Something like $200 billion will be spent in the next year on digital technologies for manufacturing—but it's an incredibly fuzzy, unclear concept: Just exactly what are we doing this for? And how do we get started?”

His Moneyball pitch was straightforward and engaging, especially if you’re a fan of baseball, or of Michael Lewis. Or Brad Pitt. Basically, as this “amazing story” goes, the game had been played the same way for more than 100 years. Statistics on pitching and hitting have been charted from the early days, while managers all played by the same book of strategy, building teams and setting lineups based on numbers like batting averages, RBIs, and home runs.

But then in the late 1990s, some “very creative folks” took a look at a century’s worth of stats and “completely reconceived” how to think about baseball.

“They asked a simple question: Does the batter get on base?” he said. “There's at least 27 at bats in the game. Each at bat is a unit of production that needs to be used as efficiently as possible.”

Likewise, most manufacturers are “incredibly rigorous,” data-driven, and goal-oriented, with a deep tradition of continuous improvement—"always trying to get better,” Sobel continued.

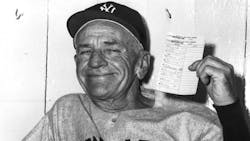

But, back to baseball, Sobel quoted the great slugger Mickey Mantle, who once said, “It's unbelievable how much you don't know about the game you've been playing your whole life.”

Indeed, that new look at baseball stats (called sabermetrics) helped the 2002 Oakland A’s, with one of the smallest payrolls in professional baseball, set a league record by winning 20 games in a row, and making the playoffs after winning 103 games on the season. The Boston Red Sox shortly after won their first World Series in 86 years applying the model, and now the new measures are included on ballpark scoreboards.

“The use of data forever changed baseball—and in almost every industry, there's a story like this” Sobel said.

Common manufacturing statistics are focused on things like asset utilization, materials waste, production quality and output.

“We've all been trying to answer those questions for a long time, but here's what's different about digital: You can see more; there's data everywhere,” he said. “Of course, using it is very challenging. And this is where my community of Silicon Valley has, unwittingly perhaps, participated in a real disservice: We made it sound easy.”

Typical complications for manufacturers include trying to get data from 50-year-old machines or a dozen software systems accumulated and modified over time. Sobel suggested that, before investing in new technology, manufacturers need to fully understand their goals and be able to “see a straight line” from that investment to the goal.

“Companies like mine better be able to show you that this is going to help with your business—and they better be able to explain how in one-syllable words. If we can't, don't do business with us,” he said.

And you don’t need to invest in “giant systems”—a few sensors on critical machines will do. The key is to tie that data “to productivity, not production.”

“It’s not how much stuff did I make today, it’s how well did I make it? Are we getting better?” Sobel said. “We work with some of the world's largest manufacturers, and it's amazing that not one of them has had an accurate measure of their productivity when we've started working with them. They have no idea.”

They had data, but they weren’t using it effectively.

“Stop paying attention to RBIs and start paying attention to on-base percentage, and slugging average—just measure to find out: Are each of these machines producing at the same output? What's my quality really?” he said. “And then select tools that move you toward those answers. That, respectfully, is digital transformation. Nothing more, nothing less—but it's incredibly powerful and effective.”

So take a fresh look at that lineup, and “Play ball!”

About the Author

Kevin Jones

Editor

Kevin has served as editor-in-chief of Trailer/Body Builders magazine since 2017—just the third editor in the magazine’s 60 years. He is also editorial director for Endeavor Business Media’s Commercial Vehicle group, which includes FleetOwner, Bulk Transporter, Refrigerated Transporter, American Trucker, and Fleet Maintenance magazines and websites.

Working from Beaufort, S.C., Kevin has covered trucking and manufacturing for nearly 20 years. His writing and commentary about the trucking industry and, previously, business and government, has been recognized with numerous state, regional, and national journalism awards.