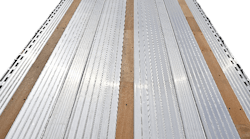

Touch 'n Seal, manufactured by Convenience Products, has introduced a new and improved formula of its slow-rise spray foam. The new 1.75 pcf low-pressure, two-component foam is perfect for repairing reefer trailers.

The new gel time is 120 seconds.

"The longer expansion time makes it even more capable of filling closed cavities, channels, and other tight spaces," said Touch 'n Seal Marketing Manager Jonathan Fore.

Slow Rise 120 is intended for pour-in-place applications where the foam needs to completely fill cavities or spaces without creating voids.

Touch ‘n Seal Slow Rise 120 is a closed-cell, medium-density polyurethane foam system which passes ASTM E84, Class I fire test. Slow Rise 120 is well-suited for repairing foam insulation in tanker trucks and refrigerated trailers where voids or cavities cannot be accessed with spray applied foam. The applicator nozzles have been designed to fit with flexible tubing for better control of the application.

Touch ‘n Seal 1.75 pcf Slow Rise 120 is available in 200- and 600- board foot foam kits, 750- board foot cylinders for the Constant Pressure Dispensing System, and 17-, 60-, and 120- pound refillable cylinders.