Manufacturing demand still strong; supply chain an ongoing challenge: ISM

Economic activity in the manufacturing sector grew in July, with the overall economy notching a 14th consecutive month of growth, say the nation's supply executives in the latest Manufacturing ISM Report On Business by the Institute for Supply Management.

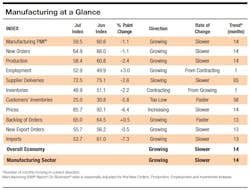

The July Manufacturing PMI registered 59.5 percent, a decrease of 1.1 percentage points from the June reading of 60.6 percent. A reading above 50 percent indicates that the manufacturing economy is generally expanding; below 50 percent indicates that it is generally contracting. A Manufacturing PMI above 43.1 percent, over a period of time, generally indicates an expansion of the overall economy.

“Business Survey Committee panelists reported that their companies and suppliers continue to struggle to meet increasing demand levels,” Timothy R. Fiore, chair of the ISM manufacturing business survey committee, said. “As we enter the third quarter, all segments of the manufacturing economy are impacted by near record-long raw-material lead times, continued shortages of critical basic materials, rising commodities prices and difficulties in transporting products. Worker absenteeism, short-term shutdowns due to parts shortages and difficulties in filling open positions continue to be issues limiting manufacturing-growth potential.”

Still, optimistic panel sentiment remained strong, with 13 positive comments for every cautious comment.

What respondents are saying

- “Strong sales continue, and inventories are low as the chip shortage is keeping production numbers down — we have idled several of our assembly plants to reduce the strain on the chip supply base.” [Transportation Equipment]

- “Supply chains are slowly, very slowly filling up. Like a water hose, starting upstream and slowly flowing downstream. Rumor is a full return to ‘normal’ may be nearer to year’s end, but the situation is progressing. Transportation (equipment and drivers) is the current pinch point, more so than material shortages.” [Chemical Products]

- “Strong operations, (with) new programs, orders and launches. Continue to have hiring difficulties and are unable to fill production and salaried jobs (due to) a lack of candidates. Raw materials are still in short supply, with longer lead times.” [Fabricated Metal Products]

- “Supply chain continues to be extremely challenging in a variety of categories. Having to place orders months ahead of time just to get a place in line.” [Machinery]

- “Very busy with new orders. Material costs continue to rise, and supplies are sometimes delayed. Labor issues are still affecting us the most with finding proper labor. Labor— costs are increasing as we are competing locally for top talent.” [Miscellaneous Manufacturing]

- “Business levels continue to be very strong, but we also continue to struggle finding employees. We can only fill 75 percent of our order requirements due to the labor shortage.” [Primary Metals]

Broadly, demand expanded, with the (1) New Orders Index growing, supported by continued expansion of the New Export Orders Index, (2) Customers’ Inventories Index remaining at very low levels and (3) Backlog of Orders Index staying at a very high level, according to the report.

Consumption (measured by the Production and Employment indexes) improved in the period. The Employment Index returned to expansion after one month of contraction; panelists continued to note significant difficulties in attracting and retaining labor at their companies’ and suppliers’ facilities, although there were signs of improvement.

Inputs — expressed as supplier deliveries, inventories, and imports — continued to support input-driven constraints to production expansion, at slower rates compared to June as the Supplier Deliveries Index softened while the Inventories Index contracted, likely due to long lead times.