ISM: Manufacturing sector reversing April’s heavy contraction

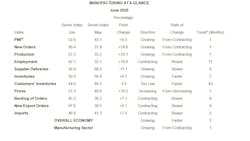

Economic activity in the manufacturing sector grew in June with the overall economy notching a second month of growth after one month of contraction, according to the nation’s supply executives in the latest Manufacturing ISM Report On Business.

The June PMI registered 52.6%, up 9.5 percentage points from the May reading of 43.1%. This figure indicates expansion in the overall economy for the second straight month after April’s contraction, which ended a period of 131 consecutive months of growth.

“June signifies manufacturing entering an expected expansion cycle after the disruption caused by the coronavirus (COVID-19) pandemic,” said Timothy R Fiore, chair of the ISM Business Survey. “Comments from the panel were positive (1.3 positive comments for every one cautious comment), reversing the cautious trend, which began in March.

“The manufacturing sector is reversing the heavy contraction of April, with the PMI increasing month-over-month at a rate not seen since August 1980, with several other indexes also posting gains not seen in modern times.”

Other highlights from the report:

- The New Orders Index registered 56.4%, compared to the May reading of 31.8%.

- The Production Index registered 57.3%, compared to the May reading of 33.2%.

- The Backlog of Orders Index registered 45.3%, compared to the May reading of 38.2%.

- The Employment Index registered 42.1%, compared to the May reading of 32.1%.

- The Supplier Deliveries Index registered 56.9%, compared to the May figure of 68%.

- The Inventories Index registered 50.5%, compared to the May reading of 50.4%.

- The Prices Index registered 51.3%, compared to the May reading of 40.8%.

- The New Export Orders Index registered 47.6%, compared to the May reading of 39.5%.

- The Imports Index registered 48.8%, compared to the May reading of 41.3%.

“Demand expanded, with the New Orders Index growing at a respectable level, supported by New Export Orders Index contraction softening; Customers’ Inventories Index returning to a level considered a positive for future production, and Backlog of Orders Index softening, although still contracting. Consumption (measured by the Production and Employment indexes) contributed positively (a combined 34.1-percentage point increase) to the PMI calculation, with most companies’ employees returning to work in June,” Fiore said.

“Inputs—expressed as supplier deliveries, inventories and imports—weakened, due to supplier delivery issues abating and import levels improving. Inventory levels reached parity with supply and demand. Inputs contributed negatively (a combined 11-percentage point decrease) to the PMI calculation but were more than offset by the demand and consumption improvement. (The Supplier Deliveries and Inventories indexes directly factor into the PMI; the Imports Index does not.) Prices entered expansion again, but at marginal levels, supporting a positive outlook.”

Transportation Equipment, Primary Metals, Fabricated Metal Products and Machinery were the four manufacturing industries reporting contraction in June. Only miscellaneous manufacturing was among the 13 industries reporting growth in June.

“As predicted, the growth cycle has returned after three straight months of COVID-19 disruptions,” Fiore said. “Demand, consumption and inputs are reaching parity and are positioned for a demand-driven expansion cycle as we enter the second half of the year. Among the six biggest industry sectors, Food, Beverage & Tobacco Products remains the best performing industry sector, and Computer & Electronic Products, and Chemical Products returned to respectable growth.

“Transportation Equipment and Fabricated Metal Products continue to contract, but at much softer levels.”

Here are some selected comments from respondents:

- “While we are seeing signs of an uptick in business activity, it is a slow recovery at this point.” (Chemical Products)

- “Gradually ramping production back in our plants. Most of our supply base continued to operate during COVID-19, so we are not seeing a significant supply risk. Will be monitoring supply chain financial health closely.” (Transportation Equipment)

- “Thankfully, we are in quite a few industries, so impact wasn’t as harsh on us and more stable. However, during the last two weeks, our bookings have grown, and supply seems to be more readily available.” (Fabricated Metal Products)

- “Difficulty keeping up with a significant increase in demand related to COVID-19. Industry is up 62.5% vs [a] year ago. Supply challenges throughout the supply chain. Supply could be hindered if another wave of COVID-19 hits in the fall.” (Food, Beverage & Tobacco Products)

- “Market demand for refined products has increased as statewide quarantines have been lifted, but it is still below normal volumes.” (Petroleum & Coal Products)

- “Orders have picked up and are trending toward normal production requirements [volume similar to 2019 production].” (Plastics & Rubber Products)

- “We are seeing an increase in orders as the economy starts to get rolling again. Slow and steady, sales are increasing. So far, so good.” (Primary Metals)

- “Looks like May was the bottom in terms of orders. June is stronger, and our order books are rebuilding.” (Machinery)

- “Demand is down significantly due to COVID-19 but is starting to stabilize. We are hopeful for recovery in the second half of the year.” (Miscellaneous Manufacturing)

- “The building industry continues to defy expectations, as we continue to rebound stronger from the previous month. Being an essential business across most states and a surge in DIY projects has fueled the industry forward. While the industry will follow the greater economy, we do believe it will be more resilient than most due to potential migration from larger cities and an undersupplied housing market.” (Wood Products)