Quick reference for 2019-2020 snowplow mounting

The snow-and-ice season is coming, so it’s time to brush up on snowplow mounting basics.

Fiat Chrysler Automobiles recently updated the lighting and driver assistance functionality for snowplow systems connected to Ram trucks, Ford is updating its snowplow connector for 2020 model-year Super Duty trucks, and General Motors revised its mounting guidelines for 2020 MY Chevrolet Silverado and GMC Sierra trucks.

Ram’s refreshes are part of an ongoing commitment to ensuring the safest snowplow upfits.

“Ram engineers design dedicated snow plow circuits that allow an easy interface to our truck’s electrical system,” said engineer Chris Borczon, a supervisor with the Ram Truck Commercial Vehicle Team. “This avoids the potentially negative attempts to tap into a truck’s power systems.”

The following list, compiled using the most recent information available at press time, is for quick reference only. For a comprehensive list of the specific guidelines for each RAM, GM and Ford model, including any further updates, refer to the body builder publications supplied by each manufacturer at ramtrucks.com/body-builders-guide.html, gmupfitter.com and fordbbas.com, respectively.

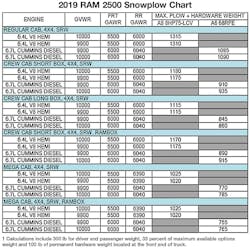

Ram

To ensure installation of snowplows and their mounting hardware doesn’t result in a vehicle weight distribution or front-axle loading that’s determinantal to brake performance or exceeds front gross axle weight rating (GAWR), it’s important to keep a couple key requirements in mind.

The loaded vehicle, including all aftermarket accessories, the snowplow system, passengers and cargo must not exceed the gross vehicle weight (GVW), or the front or rear GAWRs, specified on the Safety Compliance Certification label located in the driver’s side door opening.

The empty truck, with all permanently attached accessories and snowplow components must not exceed 62% of its total weight on the front axle to comply with FMVSS/CMVSR 105 Brake Certification. Permanently attached snowplow parts are those parts not easily removed when the blade is removed. The permanently attached parts include the sub-frame, hydraulic pump, hydraulic lift cylinder, lamps, wiring and snowplow controls.

“Ram engineers design dedicated snow plow circuits that allow an easy interface to our truck’s electrical system,” Borczon said. “This avoids the potentially negative attempts to tap into a truck’s power systems.”

If the front axle load exceeds either 62% of the empty truck total weight, or the front GAWR, ballast-compensating weight must be securely attached at the rear of the truck to bring the front axle weight within defined specifications.

“The Ram truck brand has cultivated relationships with snow plow manufacturers to provide adequate space and structure to ensure the plow can be installed to frame structure that can support the plow loads through the vehicle’s lifetime,” Borczon said.

Notes for heavy-duty snowplows:

- At any time, the maximum number of occupants in the truck must not exceed two

- Under no circumstances should a vehicle exceed its gross vehicle weight rating (GVWR), or front or rear GAWRs

- Snowplow prep packages are not available with Power Wagons

- Cargo capacity will be reduced by the addition of options

- Ballast should be securely attached inside the box at 9 inches from the rear tailgate for pickups

- The total weight of permanently attached hardware should not exceed 125 pounds

- Max snowplow weight should not exceed established values for each models

Snow plow lighting interface

Traditionally, when installing a snow plow, a vehicle’s headlights are disabled in favor of those mounted on the snow plow. To do this, the plow manufacturer provides an electrical interface that installs between the OEM headlight harness and the headlights. When the plow is installed, the power to the vehicle headlights is re-routed through the plow’s electrical interface to the snow plow lights. As a result, vehicle headlights are disabled.

But as headlight designs grow more complex, with new lighting sources, connectors and integrated diagnostics, it’s increasingly difficult to install snow plow lights using traditional methods. So Ram developed a wiring interface that provides the signaling necessary to control the snow plow lighting relays without modifying the OEM headlight harness. Ram recommends not modifying its front lighting circuitry and instead using snow plow lighting blunt cut control wires.

This interface is standard on all 2500, 3500, 4500 and 5500 trucks, Ram said.

The snow plow wiring interface has six wires, one for each headlight function, and an enable wire. When battery positive is applied to the enable wire, the vehicle high and low beams automatically disable and the other five plow output wires enable. The five lighting output wires cannot be used to control exterior lighting without a plow attached. They are only enabled in Snow Plow Lighting Enabled mode when the vehicle’s headlights are disabled.

And new for 2019, when the snow plow lighting enable circuit (L312 black/violet) is powered with 12 volts-plus, signaling to the vehicle that a snow plow is present, a Snow Plow Lighting Enabled icon will appear in the cluster. When the vehicle is in snow plow present mode, the Adaptive Cruise Control, Front Park Assist and Front Collision Warning systems will be turned off.

Refer to FCA’s Snow Plow Lighting information at ramtrucks.com/body-builders-guide.html for more information.

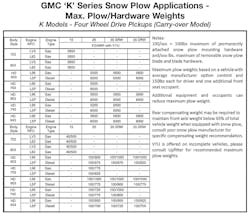

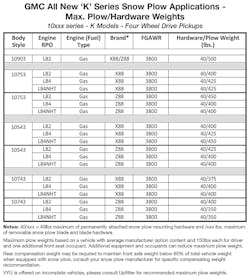

General Motors

GM recommends that when a snowplow is mounted on a vehicle, only one passenger should accompany the driver. More than one passenger may exceed front GAWRs.

Prior to installing a front-mounted snowplow, the following process should be followed, and necessary information obtained:

- Establish vehicle curb weight

- Establish chassis manufacturer’s front and rear axle weight ratings

- Chevrolet and GMC truck dealers can provide availability, specifications, GVWRs, and front and rear GAWRs. For vehicles already built, this information can be found on the certification label installed on the driver’s door/door frame or provided on the cover of the Incomplete Vehicle Document.

The following information should be obtained and provided by the manufacturers of snowplows and salt spreaders:

- Specifications, weights and center of gravity data

- Vehicle installation guidelines and instructions

- Calculation of weight distribution for the front and rear axles

The loaded vehicle with driver, passenger, aftermarket accessories, snowplows, spreader and cargo must not exceed the GVWR, or front and rear GAWR.

In addition, the completed curb weight vehicle, with all installed aftermarket accessories, snowplow and spreader, and with 400 pounds distributed in the driver-passenger area of the vehicle, must have a center of gravity that is located within the trapezoid formed by the coordinates A, B, C, D, H1 and H2, plus it must be to the rear of vertical line E and forward of vertical line F as defined in the Allowable Center of Gravity charts. If the center of gravity does not fall within the specified trapezoid, ballast weight may be required to shift the center of gravity until it falls within the specified trapezoid.

The snowplow manufacturer and the installer of the aftermarket equipment should determine the amount of rear ballast required to ensure that the vehicle, with the attached snowplow and aftermarket equipment, complies with the Allowable Center of Gravity Trapezoid and the resulting front and rear weight distribution ratio as defined in the Allowable Center of Gravity Charts published in the GM manual.

The use of rear ballast weight may be required to prevent exceeding the GAWR of the front axle and to ensure the center of gravity location of the completed vehicle, with the attached snowplow and other installed equipment, complies with the Allowable Center of Gravity Trapezoid and the resulting front and rear weight distribution ratio, even though the actual front weight may be less than the GAWR of the front axle. In either case, the rear ballast weight should be securely attached in the cargo box or behind the rear axle of the vehicle in a manner that prevents it from moving during driving and stopping.

To help avoid personal injury, refer to the Z-height setting procedure before adjusting torsion bars. If torsion bars are adjusted for aftermarket equipment, be sure to return them to specification when the equipment is removed. Otherwise, a front shock absorber may dislodge and damage a front brake line. This could result in an accident when minimum stopping distances are required.

Recommended best practices for ‘K’ Series snowplows include:

- OEM steering gear, suspension and powertrain component mounting holes and associated OEM fasteners should not be used to attach snowplow-mounting equipment.

- A suggested minimum allowance of 10 millimeters of clearance to stationary OEM components like the bumper assembly, steering box and cooling system components is highly recommended. Note these components have varying positional tolerances.

- A suggested allowance of 20 mm minimum clearance to OEM components subject to movement. Example: Steering gear, suspension (A-arm, axle, strut and stab bar assemblies) at full jounce is highly recommended. Note these components have varying positional tolerances.

- Snowplow and associated mounting equipment should not exceed front axle available payload rating of vehicle as optioned. Plow blade height, width and mass should be in accordance with snowplow manufacturers’ recommended requirements for specific vehicle.

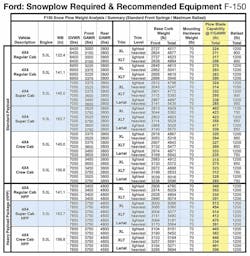

Ford Trucks

For F-150, the minimum required equipment is 4x4 only and the Snowplow Prep Package (68P):

- Requires 5.0L V8 engine (995).

- XL trim (only)—Requires rear-window, fixed privacy glass with defroster (924/57Q)

- XLT 300A base—Requires rear-window defroster (57Q)

- Lariat trim (only)—Electronic Shift-On-The-Fly (ESOF) replaces standard 2-speed automatic 4WD

- Lariat Technology Package (68T) not available with Snowplow Prep Package (68P)

- Available on Regular, SuperCab and SuperCrew models (5.5’, 6.5’ and 8.0’ boxes)

- Available with XL, XLT, and Lariat Trim

- Both regular and heavy duty payload packages

- “Snowplow” mode button on instrument panel will disable (load shed) the following features to maintain required electrical charge margins during plow operation/use: 110V inverter, fog lamps, heated steering wheel, heated front/rear seats, and massaging seats. Snowplow mode button also activates relay to snowplow controls.

NOTE: The engine Outside Air Temperature (OAT) sensor is subject to error unless relocated to unblocked airflow.

Completed vehicle weight:

- Recommended plow assembly and aft-of-rear axle ballast weight limits are shown in the attached chart. These snowplow weight limits are based upon a vehicle built with noted trim levels with no additional Ford option content, a total of 300 pounds for a driver plus one front seat passenger (150 pounds each), ballast weight rearward of the rear axle, and additional assumptions for commercially available snowplow assembly weights and mounting location.

- The vehicle must not be operated when overloaded. A vehicle is overloaded when the weight of the completed vehicle with aftermarket equipment installed, plus driver, passengers, and cargo, exceeds either the FGAWR, RGAWR, or GVWR established by Ford Motor Company and displayed on the Safety Compliance Certification Label.

- The addition of ballast weight placed rearward of the rear axle is required to prevent exceeding FGAWR, and to provide good vehicle braking and handling. The ballast should be attached securely to the vehicle with consideration for the normal driving dynamics of snowplowing, and occupant safety in accidents.

Total accessory reserve capacity:

- For Ford completed vehicles of 10,000 GVWR or less, the weight of permanently attached aftermarket equipment must not exceed the Total Accessory Reserve Capacity (T.A.R.C.) displayed on the Safety Compliance Certification Label to maintain the compliance representation that came with the Ford-built vehicle. Exceeding T.A.R.C. will require re-certification. This applies only to the permanently attached equipment, such as the snowplow frame mounting hardware, and not to the removable portion of the snowplow blade assembly.

Front-end wheel alignment and headlight aim:

- Front end wheel alignment (toe) and headlight aim may require readjustment after installation of snowplow equipment. Failure to reset front wheel alignment may cause premature uneven tire wear. If required, reset to chassis manufacturer’s specifications found in the Ford Shop Manual.

Electrical connections:

- Installation of any inductive load devices such as electric motors, or electric clutches for clutch pumps, must not be connected to Ford vehicle wiring or fuse panels. Power for such devices should be taken directly from the battery or starter motor relay power terminal. Control of these devices should be achieved via relays. No direct current path should exist between Ford vehicle wiring and the installed load that is not filtered by the battery. These recommendations are intended to eliminate or minimize any induced reverse voltage into the Ford circuitry.

- Vehicles equipped with the Snowplow Prep option will include the Snowplow Mode switch located on the dash. Activating Snowplow Mode will provide 10 Amp B+ power to a dedicated feed for the plow controller. It is a blunt cut Yellow/Orange wire, and is found taped to the headlamp switch harness, behind the left side of the driver’s side dash panel. When activated, the vehicle will enter a special load shedding strategy to ensure continuous operation of the plow during periods of high electrical demand.

- For Super Duty F-250/350/450/550, the minimum required equipment is 4x4 (all pickups, F-350 chassis cab) and the Snowplow Prep Package (473), which includes:

- Front spring/GAWR upgrade (refer to the Weight Ratings charts for specific spring/GAWR selection for each model).

- 6.2L gasoline: Extra HD 200-amp alternator; optional 240-amp Extra HD alternator.

- 6.7L diesel Pickup: Extra HD 220-amp alternator; optional 332-amp dual alternators.

- 6.7L diesel chassis cab: 332-amp dual HD alternators; optional 377 amp dual extra HD alternators.

Recommended equipment:

- All-terrain tires and roof clearance lights (optional with SRW Pickup models, required with F-350 DRW and F-450).

Standard equipment:

- Front and rear stabilizer bar (rear standard on Chassis Cab and DRW pickup models).

- Roof clearance lights (standard on Chassis Cab and required on Pickup models).

- Steering damper.

- Engine oil cooler, auxiliary automatic transmission oil cooler and maximum capacity engine coolant radiator are standard.

- All available axle ratios are acceptable.

- When snowplowing, operate automatic transmission with shift lever in Overdrive position.

Completed vehicle weight:

- Snowplow weights (maximum recommended): Refer to the tables below. The vehicle must not be operated when overloaded. A vehicle is over-loaded when the weight of the completed vehicle with aftermarket equipment installed, plus driver, passengers and cargo, exceeds either the FGAWR, RGAWR or GVWR displayed on the Safety Compliance Certification Label.

- The addition of ballast weight placed rearward of the rear axle may be required to prevent exceeding the FGAWR, and provide good vehicle braking and handling. The ballast should be attached securely to the vehicle with consideration for the normal driving dynamics of snowplowing and occupant safety in accidents.

- For Ford completed vehicles of 10,000 lbs GVWR or less, the weight of permanently attached aftermarket equipment must not exceed the Total Accessory Reserve Capacity (TARC) displayed on the Safety Compliance Certification Label to maintain the compliance representation that came with the Ford built vehicle. Exceeding TARC may require re-certification. This applies only to the permanently attached equipment, such as the snowplow frame mounting hardware, and not to the removable portion of the snowplow blade assembly.

Front-end wheel alignment and headlight aim:

- Front-end wheel alignment (toe) and headlight aim may require readjustment after installation of snowplow equipment. Failure to reset front wheel alignment may cause premature uneven tire wear. If required, reset to chassis manufacturer’s specifications found in the Ford Shop Manual.

Electrical connections:

- Installation of any inductive load devices, such as electric motors or electric clutches for clutch pumps, must not be connected to Ford vehicle wiring or fuse panels. Power for such devices should be taken directly from the battery or starter motor relay power terminal. Control of these devices should be achieved via relays. No direct current path should exist between Ford vehicle wiring and the installed load that is not filtered by the battery. These recommendations are intended to eliminate or minimize any induced reverse voltage into the Ford circuitry.

Warranty:

The Ford New Vehicle Limited Warranty applies to vehicles with snowplows installed in accordance with these guidelines. Consult your Ford dealer or the Owner’s Guide for any further questions.