BorgWarner recently introduced its Organic Rankine Cycle (ORC) waste heat recovery system for the commercial vehicle sector.

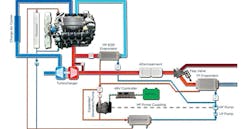

Designed as a solution for increasingly stringent emissions regulations and rising fuel costs, the ORC is a complete waste heat recovery system consisting of a tailpipe and EGR evaporators, an exhaust flap bypass valve and a turbine expander, as well as turbine expander power electronics and a condenser.

The company said the system reduces CO2 emissions, improves fuel economy by 3 to 5 percent and supports mild hybrid commercial vehicles.

“At BorgWarner, we constantly aim to drive the latest advancements in efficient mobility,” said Joe Fadool, president and general manager of BorgWarner emissions and thermal systems. “By converting wasted exhaust heat into usable electrical energy, we support our customers and protect the environment at the same time.”

BorgWarner's ORC waste heat recovery system generates electrical energy by converting energy from the fuel that would be typically wasted as heat. The system takes advantage of the phase change characteristics of fluids similar to air conditioning or refrigeration systems.

The cycle can be divided into four steps. First, the cool working fluid from the condenser is pumped to high pressure. Then, waste heat from the engine heats the working fluid to a superheated vapor, which in turn drives the turbine expander and generates electrical power. Finally, the low-pressure vapor is cooled back to a liquid state by the condenser, and the process repeats itself.

Featuring a 48-volt electrical output, BorgWarner’s ORC turbine expander is well-suited for combustion vehicles and mild hybrid commercial vehicles. Its oil-free bearing system and aerospace-inspired turbine allow for “best-in-class” efficiency. BorgWarner’s evaporators enable improved balance between durability and high performance.

The exhaust bypass valve provides a method for controlling the amount of heat entering the waste heat recovery system from the tailpipe exhaust system. At high engine loads, it is sometimes necessary to bypass the tailpipe evaporator, the company said. Its exhaust bypass valve provides a proportional flow control of the exhaust and ensures low backpressure to maximize engine performance.