The most significant changes in the manufacturers' guidelines for snowplow mounting for the 2009 model year come from Ford.

He also said that the F-150 requires minor changes because it has a fully boxed frame constructed with hydro-formed and high-strength steel side rails, giving the lightweight frame 10% more torsional rigidity.

Tyburski said Ford has worked with the National Truck Equipment Association's (NTEA) snowplow committee and with snowplow manufacturers at measuring sessions, and also had verifications done at Ford's engineering site for electrical and frame changes.

“There are some changes in terms of brackets required based on the chassis,” he said. “We gave them the frame data and they designed the brackets. I don't think it's drastically different. I think they're comfortable with what they're doing.”

Martin Warchola, director of engineering for Meyer Products, said the brackets had to be modified because of a frame rail that is configured differently.

“Some of the items that hang down in the front are different, so we have to modify the way our brackets wrap up to bolt in through the pre-existing holes in the frame,” he said. “There's a difference in the width of the frame and the construction method. Biggest difference would be in the torsion bar or shock tower that comes down. With areas that might have been clear before, there are now things that are in that real estate area. When we take our mounting brackets up, we have to redesign how they bolt into the frame, utilizing holes that are in there.

“We try at all costs not to try to make new holes to the frame. Ford and the others have been good in recent years in giving us adequate holes so we have minimal modification to the frame. It is a new frame. It's not a real major issue by any means.

“The other thing that potentially is different with a model changeover is the lighting package and electrical system. That typically creates a much larger issue, just because of what it is. Typically the snowplow folks are very good when it comes to all of the mounting side because it's all there and it's very physical and visual. The electrical side is trickier because sometimes you don't have all the info, and you find things out by happenstance. We've been advised that the ‘09 F-150 is going to follow the same pattern as the F-250/350 release was last year, so we already know what will go on electrical side and it won't be an issue.

“We were at GM and Dodge (in mid-August) doing final revisions with new frame tweaks. At Dodge, we had to cut ⅛” of one of our side members that mounts up to the frame. Other than that, everything is the same. So the changes they're making, at least in areas of concern for us, are fairly minor with this last iteration. He said the meetings between NTEA and the chassis and snowplow manufacturers have been very productive.

“They've been very responsive in the four years I've been going to meetings in trying to make allowances for us,” he said. “At the end of the day, they know it's in their best interest and our best interest to make snowplows as easy to put on and as readily available to put on as possible. It makes for a more functional work truck.”

The following list is for quick reference only. For a comprehensive list of the specific guidelines for each model, refer to the body builders book published by the truck manufacturer.

General Motors

Prior to installing a front-mounted snowplow, the following process should be followed and necessary information obtained:

-

Establish vehicle curb weight.

-

Establish chassis manufacturer's front and rear axle weight ratings.

-

Chevrolet and GMC truck dealers can provide availability, specifications, GVWR, and Front and Rear GAWR. For vehicles already built, this information can be found on the certification label installed on the driver's door/frame or provided on the cover of the Incomplete Vehicle Document.

The following information should be obtained and provided by the manufacturers of snowplows and salt spreaders:

-

Specifications, weights, and center of gravity data.

-

Vehicle installation guidelines and instructions.

-

Calculation of weight distribution for the front and rear axles.

The loaded vehicle with driver, passenger, aftermarket accessories, snowplows, spreader, and cargo must not exceed the GVWR, and Front and Rear GAWR.

In addition, the completed curb weight vehicle, with all installed aftermarket accessories, snowplow, and spreader, and with 400 lb distributed in the driver-passenger area of the vehicle, must have a center of gravity that is located within the trapezoid formed by the coordinates A, B, C, D, H1 and H2, plus it must be to the rear of vertical line E and forward of vertical line F as defined in the Allowable Center of Gravity charts. If the center of gravity does not fall within the specified trapezoid, ballast weight may be required to shift the center of gravity until it falls within the specified trapezoid.

The snowplow manufacturer and the installer of the aftermarket equipment should determine the amount of rear ballast required to ensure that the vehicle, with the attached snowplow and aftermarket equipment, complies with the Allowable Center of Gravity Trapezoid and the resulting front and rear weight distribution ratio as defined in the Allowable Center of Gravity Charts published in the GM manual.

The use of rear ballast weight may be required to prevent exceeding the GAWR of the front axle. The use of rear ballast weight may be required to ensure that the center of gravity location of the completed vehicle, with the attached snowplow and other installed equipment, complies with the Allowable Center of Gravity Trapezoid and the resulting front and rear weight distribution ratio, even though the actual front weight may be less than the GAWR of the front axle. In either case, the rear ballast weight should be securely attached in the cargo box or behind the rear axle of the vehicle in a manner that prevents it from moving during driving and stopping.

To help avoid personal injury, refer to Z-height setting procedure before adjusting torsion bars. If torsion bars are adjusted for aftermarket equipment, be sure to return them to specification when the equipment is removed. Otherwise, a front shock absorber may dislodge and damage a front brake line. This could result in an accident when minimum stopping distances are required.

Ford Trucks

Minimum recommended equipment for the F-150: regular cab 4×4, 144.5" wheelbase, 8' pickup box; or SuperCab 4×4, 163" wheelbase, 8' pickup box.

Snowplow prep package (option code 63A) includes FGAWR upgrade to 4300 lb (4300 lb spring rating).

Heavy Duty Payload package (option code 627) includes: 8200-lb GVWR; 4050-lb FGAWR (4050-lb spring rating); 4800-lb RGAWR (4900-lb spring rating); rear axle capacity upgrade to 5300 lb and 10.5" diameter ring gear 4.10 ratio, limited-slip not included but available; 17"×7.5" J 7-lug steel wheels; LT245/70R×17D BSW all-season tires (5); 5.4L, 3-valve V8 engine, 4R75E automatic transmission; Super Engine Cooling (1.42" core thickness); auxiliary transmission air cooler, oil-to-water increased to 9-channel/18-plate; battery upgrade to 72 amp-hr/650 CCA; fuel tank (35.7-gallon capacity).

Snowplow weights (maximum recommended):

-

Regular Cab 750 lb (700 lb removable plow assembly plus 50 lb permanently attached hardware).

-

SuperCab 610 lb (560 lb removable plow assembly plus 50 lb permanently attached hardware).

These snowplow weight limits are based upon a vehicle built with maximum buildable Ford option content, driver plus one front seat passenger, 150 lb each, 800 lb of ballast weight rearward of the rear axle, and additional assumptions for commercially available snowplow assembly weights and mounting location.

The vehicle must not be operated when overloaded. A vehicle is overloaded when the weight of the completed vehicle with aftermarket equipment installed, plus driver, passengers, and cargo, exceeds either the FGAWR, RGAWR, or GVWR established by Ford Motor Co and displayed on the Safety Compliance Certification Label.

The addition of ballast weight placed rearward of the rear axle may be required to prevent exceeding FGAWR, and provide good vehicle braking and handling. The ballast should be attached securely to the vehicle with consideration for the normal driving dynamics of snowplowing and occupant safety in accidents.

For Ford completed vehicles of 10,000 GVWR or less, the weight of permanently attached aftermarket equipment must not exceed the Total Accessory Reserve Capacity displayed on the Safety Compliance Certification Label to maintain the compliance representation that came with the Ford-built vehicle. Exceeding TARC will require recertification. This applies only to the permanently attached equipment, such as the snowplow frame mounting hardware, and not to the removable portion of the snowplow blade assembly.

Front end wheel alignment (toe) and headlight aim may require readjustment after installation of snowplow equipment. Failure to reset front wheel alignment may cause premature uneven tire wear. If required, reset to chassis manufacturer's specifications found in the Ford Shop Manual.

Installation of any inductive load devices such as electric motors, or electric clutches for clutch pumps, must not be connected to Ford vehicle wiring or fuse panels. Power for such devices should be taken directly from the battery or starter motor relay power terminal. Control of these devices should be achieved via relays. No direct current path should exist between Ford vehicle wiring and the installed load that is not filtered by the battery. These recommendations are intended to eliminate or minimize any induced reverse voltage into the Ford circuitry.

Dodge Trucks

The loaded vehicle, including all aftermarket accessories, the snowplow system, passengers, and cargo, must not exceed the gross vehicle weight (GVW), front or rear gross axle weight (GAW) ratings specified on the Safety Compliance Certification label located in the driver's side door opening.

Notes for heavy-duty snowplows:

-

At any time, the maximum number of occupants in the truck must not exceed two.

-

Under any circumstances, vehicles should not exceed GVWR (Gross Vehicle Weight Rating), front or rear GAWRs (Gross Axle Weight Ratings).

-

Snowplow prep packages are not available with Sport (AAG) package.

-

Cargo capacity will be reduced by the addition of options.

-

Ballast should be securely attached inside the box at 9" from the rear tailgate for pickups.

-

The total weight of permanently attached hardware should not exceed 125 lb.

-

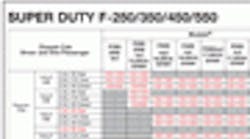

Max snowplow weight should not exceed values for models shown in this section.