Rotary’s new R5000HD Commercial Truck Alignment System is designed to make aligning heavy-duty trucks, buses and other vehicles easy, saving fleets, truck dealers and independent repair facilities time and money.

“Many heavy-duty shops are looking to increase revenue by adding wheel alignment services or improving their alignment efficiency,” said Jeff Vervoort, Rotary wheel service sales and technical trainer.

“Heavy-duty alignment is a lucrative business. The average cost for a typical wheel alignment on a car is about $100-$120, but for a tractor trailer, it’s $250 and up, so the equipment can pay for itself pretty quickly.”

One way it does this is by eliminating the need for rolling compensation required by other systems.

Typical alignments are performed by mounting a four-point clamp to the outer edge of the wheel. But if the wheel is damaged, the clamp is attaching to an untrue surface. The result can be an inaccurate alignment unless technicians perform the time-consuming and sometimes back-breaking process of compensation.

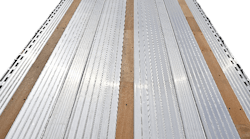

The R5000HD alignment system contacts the wheel at the bolt circle, which is the strongest, truest portion of the wheel, instead of the outer edge. That takes the guesswork out of alignments, and eliminates the added labor time, expense and physical effort associated with compensation.

The system also reduces labor time by electronically measuring axle offset every alignment. Most systems require the technician to manually measure axle offset, which often takes 10 to 20 minutes. The R5000HD automatically measures axle offset and notifies the tech when there’s a problem.

The system is ideal for aligning trucks with a GVWR of 19,500 pounds or more. It doesn’t require a tower at the front of the bay, has no minimum bay size requirements, and the portable aligner console can be positioned anywhere in available bay space – floor, pit or lift.

The R5000HD features infra-red transmission among measuring heads. Each measuring head has controls to allow technicians to control the alignment process without returning to the console, which can be located up to 59 feet away.