Buyers Products offers forged grab hooks

Buyers Products Co has added two forged steel grab hooks to its line of products.

A 1/2" hook boasts a 9,200-lb working load limit, while the 3/8“ hook carries a 5,400-lb working load limit. Both are Grade 43 weld-on hooks.

These hooks are designed to grab a single link of chain on the side to form a loop for dragging, pulling, or towing. They are ideal for dump bodies and loader buckets.

E-mail Brian Smith at [email protected] for further information.

Bee Line's LC7000 has wheel aligners abuzz

Bee Line Co has released the LC7000 Series heavy-duty truck wheel alignment system. New alignment heads feature a sleek new look and even more sleek technology. The most impressive feature on the head is the color LCD screen that operates like a mini monitor for the technician. Each screen in the WindSpeed 7000 Software is displayed on the head and prompts the technician through an alignment just as if he were looking at the monitor. This advantage reduces the time to gauge the alignment of a vehicle.

Another key improvement are the self-seeking lasers in the end of the tubes. Instead of dialing in the lasers manually, the lasers automatically find the optimum position on the opposite tube. New lithium ion batteries keep the heads charged for up to 10 hours.

E-mail Mick Dalton at [email protected] for more information.

Fabick can protect truck, trailer bed floors

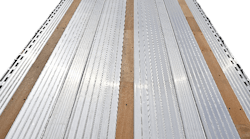

Fabick Protective Coatings, now entering its 13th year in industrial coatings, offers its exclusive, patented “Poured-on” technology to protect new truck and trailer bed floors, as well as giving renewed life to old ones.

Developed specifically for dump and service truck beds and trailer floors, the Poured-on coating protects fleet investments. The finish provides cleaner load release, can handle up to 350° F, and wears better than steel. With no bolts or holes, it is easy to maintain and repair.

Fabick will come to a customer's facility to set up and train. Systems for a fleet are cost-effective, and this application requires minimal prepping and masking.

Access www.fabick.com for further information.

Brenner provides Lean Duplex steels to cut cost of new bulk tank trailers

Brenner Tank has introduced a next-generation tank compliant with DOT 407 regulations, using duplex stainless steels and reducing the total cost of new bulk tank trailers.

The price of the most common stainless steel tank trailers has almost doubled in the past four years. Brenner Tank recognized that these material cost increases could not be borne by its customers, so it resolved to find an answer.

After more than one year of research, the company decided on Lean Duplex as the primary solution. Lean duplex is a variant of a type of stainless steel duplex that was developed more than 20 years ago for corrosive applications. This family of stainless steels generally has more chromium but less nickel than type 316L.

“Along this journey to a solution, Brenner had to overcome several challenges,” according to John F Cannon, the company's vice-president of sales and marketing. “For example, Brenner had to secure a special permit from the United States Department of Transportation to use these relatively new variants of duplex stainless steel for cargo tanks transporting chemicals and other hazardous materials.” The company also had to work with its principal suppliers to achieve a surface finish acceptable to the tank trailer industry.

Lean Duplex offers several advantages over type 316L stainless steel, besides its lower cost. It has higher tensile and yield strengths, increased pitting resistance, and an improved ability to sustain temperature changes than type 316L.

E-mail Mary Mullen at [email protected] for complete information.

Ramsey adds service crane hoists to its line

Ramsey Winch Co has introduced new service crane hoists designed for speed, light weight, and easy maintenance. SCH hoists use a single lubricant that is highly suitable for a range of temperatures.

SCH hoists are available in several different capacities in order to meet various applications. For more information, visit www.Ramsey.com/industrial.

Fifthwheel light in weight, not performance

SAF-Holland Inc introduces the Holland FWAL lightweight aluminum fifthwheel.

Designed by SAF-Holland and forged by Alcoa, the fifthwheel is designed for standard duty and forged from the same aluminum alloy as Alcoa's aluminum truck wheels. Rated for 55,000 pounds maximum vertical load and 150,000 pounds maximum drawbar pull, it is backed by SAF-Holland's five-year/500,000 mile Performance Guarantee.

At 100 pounds lighter than other fifthwheels, haulers can load 100 pounds more per trip.

The fifthwheel was field-tested with fleets using tankers, bulk haulers, and flatbeds hauling loads, including beverages, steel, cement, fuel, liquid and bulk food products, and refuse.

This fifthwheel uses patented NoLube technology that eliminates the use of grease on the top plate, between top plate and bracket, and in the lock mechanism.

E-mail Evelyn Lyzenga at [email protected] for further details.

Lift and Latch module does two functions

AIRman Inc introduces its new product line, the LAL (Lift and Latch) module. This module performs two functions and automatically controls sequencing without any mechanical or electrical signals.

A “latching” cylinder is activated first to release before “lift” cylinders raise. In reverse, the “lift” cylinders lower before the “latch” cylinder closes. Sequencing is based on pressure decay and is controlled by a built-in check valve with restricting orifice. The module may be operated either electrically or manually.

Internal components of this module are based on AIRman's standard valve product line and include aluminum construction, stainless steel fasteners, low-temperature seals, and water-resistant grease. The solenoid coil is warranted against burnout for the life of the valve. E-mail Chad Dusseau at [email protected] for more details.

Large steel platform offered on SLP liftgates

Leyman Lift Gates has introduced a new heavy-duty large steel platform now available on SLP Heavy Duty Hide-A-Way (Tuck-Under-style liftgates).

The company has two styles: one for low bed height applications and one for low bed height applications. This allows the platform to be level at both low and high bed heights.

SLP models are low maintenance, heavy duty steel platform liftgates. Available lifting capacities are 2,500 and 3,500 pounds. The SLP Hide-A-Way is virtually maintenance-free, featuring greaseless major pivot points. The power unit provides thermal protection for the motor.

The SLP 2500W lift gate with a wedge platform measures 80 inches wide by 52 inches deep and accommodates bed heights ranging from 44 inches to 56 inches. The SLP 2500WLB liftgate with a wedge platform measures 80 inches wide by 50 inches deep and accommodates bed heights ranging from 36 inches to 44 inches. The SLP 3500W liftgate with a wedge platform measures 80 inches wide by 52 inches deep and accommodates bed heights ranging from 46 inches to 56 inches.

E-mail Jennifer Duke at [email protected] for additional information.

Coach supplier Valid Mfg improves the seal one never wants to see

Keeping a personal motorcoach's interior absolutely weatherproof is the key reason why Valid Manufacturing recently redesigned the critical inflatable seals that keep out water and dust once the slide-out rooms are extended. The firm switched from a dovetail mounting system to a continuous clamping system using a new Pawling Pneuma-Seal type PRS537 inflatable seal with a robust T-shape mounting cross-section. The cross-section measures 1.025 inches high when deflated and 1.575 inches across the mounting foot. When inflated, the height expands half an inch.

Made of EPDM, the inflatable seals operate as part of the fully automatic “extend” or “retract” cycle for the slide-out rooms, initiated from the driver's instrument panel. Once the rooms reach the fully extended position, the seals are automatically inflated to 30 psi to close the gap between the coach body and the slide-out room, blocking all outside contaminants from entering. To speed up the retraction cycle, the seals are quickly deflated by vacuum. Each cycle takes just 25 seconds, and one hardly hears a thing and never sees that critical seal.

A recent refinement promises to improve reliability and simplify assembly still further. The original PRS537 seals featured a flat-top surface when deflated, which expanded up to 3/8 inch upon 30-psi inflation to close the gap. An improved cross section, being phased in now and designated as RV787, has a slightly wavy top surface that expands a full half an inch.

E-mail Doc Ardrey at [email protected] for further information.

Pleated tarps canimprove load coverage

Pleated tarps from Roll-Rite act like a straight tarp, then expand up to 10' along the full length of the tarp, self-deploying on both sides to easily cover heaped loads. For tiedown applications, they are easily expandable to secure a load on the sides by simply pulling the straps from ground level and securing them to the truck body or trailer.

These pleated tarps have several advantages over traditional flapped tarps. First, they are less expensive to purchase. They don't require bulky shock cords to secure the tarp over the load. Since the extra material is easier to access from ground level, they don't require an operator to strain to reach the center of a flapped tarp to deploy it. The Roll-Rite system's built-in tension helps refold the tarp as it rolls up, without the need to first manually fold over flaps.

Roll-Rite pleated tarps are single-piece construction and custom-manufactured. They are available in general purpose Premium Mesh, or in Super Tough Mesh for demanding applications like scrap and debris hauling. Tarp edges are reinforced with double-stitching or heat-welded for strength and durability. The rear tarp rod pocket is completely lined, and the rear corners feature 18-inch reinforcement.

E-mail Cindy Cook at [email protected] for more information.