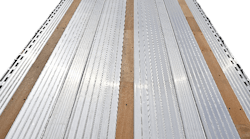

OPS Public Safety now is offering black powder coating as a standard on all of its drawers.

While powder coating always was an option for customers, OPS said, it’s now on each drawer face and safety barrier the company manufactures.

The move is intended to increase the longevity of all drawers and reduce the reflection of the aluminum, said Shane Lawrenson, OPS Public Safety’s director of business development.

“Seven out of 10 customers have been asking for this, and now that we have our own industrial powder coating booth up and running, it’s time to make it happen,” Lawrenson said. “We know that vehicle break-ins are on the rise in some parts of the US, so this will help make our drawers more discreet. The powder coating will offer a protective layer that prevents corrosion, which increases the drawer’s durability and ensures the drawer will look better for longer.”

This change also will make it easier for customers to maintain the drawers, the company said, as no special cleaners will be needed. Soap and water will suffice. Plus, because OPS Public Safety now is able to do its own powder coating in-house, it will be able to better manage the process, improve lead times and offer customized color options.

The powder coating is a super-durable polyester TGIC product that provides superior outdoor weathering capabilities, excellent exterior color and gloss retention, solid overbake resistance and good chemical resistance, OPS claimed. The application process is tightly controlled and utilizes an active filtration and evaporative process, which virtually eliminates waste streams.

“Powder coating is all around better,” Lawrenson said. “And in the end, we’re thrilled to now be able to provide it to all of our customers on all of our products.”