Link Mfg, a leader in specialty-engineered suspensions, plans to unveil details of its updated and improved 20K self-steer suspension in March.

The company said its enhanced 20K axle incorporates technological and component upgrades available in its lighter-capacity suspensions. The upgraded 20K is intended to consolidate Link’s self-steer suspension lineup, creating a “uniform offering with industry-leading advantages.”

“We listened to the marketplace and responded by adding compelling features to our existing family of self-steer auxiliary suspensions, along with unparalleled installation and performance advantages,” said Jim Huls, president of Link.

“Their structural durability, corrosion resistance and standardization characteristics will impress bodybuilders, fleets and drivers alike.”

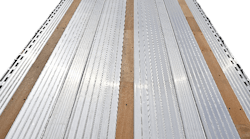

Link’s family of 8K, 10K, 13.5K and 20K self-steer auxiliary suspensions features Swift Mount technology, allowing installation to be completed in as little as two hours, compared to between six and eight hours for competing systems. Swift Mount interchangeable ride height brackets incorporate improvements in the way the frame brackets attach to the suspension hanger. The brackets can be used to mount any Link suspension, and by maintaining four sets in inventory, installers can be prepared for nearly any installation.

Link’s Swift Mount design uses a unique stepped-edge on the frame bracket, offering installers a visual indicator to help center the suspension on the truck. By comparing the frame bracket-to-hanger location for both the driver and passenger sides, the suspension is easily centered, greatly reducing installation times.

Rear air spring brackets are compatible with wide flange frame rails, accomplished by having the air fittings oriented to the outside. The air fittings also can be repositioned to the inside. For ease of service, the air springs can be removed and replaced without removing the bracket from the truck. An optional bulkhead air control system also is available, fitting within each axle’s compact mounting envelope. All air fittings are push-to-connect, and air tanks are designed to mount slightly above cross members, protecting them in cases where the suspension bottoms out.

All Link self-steer auxiliary suspensions are equipped with cast lift arms and Link-KOAT migratory self-healing metal treatment. Link-KOAT provides corrosion resistance and rust protection, even when surfaces are exposed to excessive abrasion, harsh chemicals and other severe-duty environmental factors.

The 8K and 10K members of the auxiliary suspension family share the same hardware and are designed for more robust performance than competitors, Link said, featuring heavy-duty bearings. To support its range of applications, Link plans to make its 13.5K suspension with optional premium disc brake package available in April.

Link’s family of auxiliary suspensions weighs approximately 6% less than comparable 8K, 10K, 13.5K and 20K self-steer axles, the company said. Link also integrates industry-standard wheel end and brake components into its suspensions.

“At Link, our legacy of building reliable, durable and intelligently designed suspensions continues to attract broad industry attention and further market penetration,” Huls said. “We are structured to meet growing demand, while remaining nimble and able to respond to customer orders with rapid shipping times and ultra-responsive customer support. We’re proud of what we’re building and what we’ve built.”

To ensure delivery timetables, Link recommends allowing a five-day lead time for product delivery.