David Nichols is glad and relieved that he began teaching his two sons the truck equipment business as early as he did.

Because if he had put it off, there may not be a Nichols Fleet Equipment today.

“I’m not anywhere near the point of being ready to walk out the door of this company,” Nichols says. “I was thinking that I was just beginning the transition of turning the business over to my sons.”

Then the unthinkable happened. Nichols’ wife Vivienne was struck with a ruptured brain aneurysm October 22, and suddenly day-to-day operation of Nichols Fleet Equipment was in the hands of the two sons. They would run it, or they would ruin it.

“I was forced to remove myself from the business for three months,” Nichols says. “Vivienne was in intensive care for 10 days. Between ICU, a regular hospital room, and rehab, she was in the hospital from October 22 until this past Thanksgiving. After resting at home for a while, she then had follow-up surgery in December.

“I wasn’t involved with the company much at all during that time. I had bigger fish to fry.”

Fortunately, both David “Buzz” Nichols and his brother Nick had been working at the company for a number of years. Buzz went to work for the company right after graduating from college in 2006. Nick took a more indirect route—going on to graduate school, getting a master’s degree in literature, and teaching English for almost a decade.

Today Buzz manages the shop, and Nick heads up office operations and marketing.“They make a good team,” Nichols says. “They are two different personalities, but they get along great. Both are doing a good job in completely different areas of the company, and neither of them wants to do what the other one does.”Between the two of them, they kept things going at Nichols Fleet Equipment during the time David’s attention was being devoted almost entirely to his wife’s recovery.

“I had always run my own operation. I was the owner, the salesman. Everything funneled through me. When this hit, I just had to say, ‘guys, handle it. Do the best you can, and get things done.’ And they did.

“These past few months have given them an opportunity that they needed. Consultants tell the owners of family businesses that they have to take themselves out of the business and, for better or worse, let the next generation make decisions. Owners like me need to recognize that their successors are going to make mistakes—just like all of us do. In my, case, there wasn’t an option. Things worked out.”

Welcome aboard

Buzz Nichols began his career right after graduation. David put him to work right away in sales—David’s favorite part of being in the truck equipment business. But several years into Buzz’s sales career, the company had a personnel change in the shop. David could not find a qualified replacement for the shop manager. Buzz volunteered to fill the void.

“I never contemplated being a shop manager,” Buzz says. “But my experience in sales really prepared me for the role. By the time I was asked to manage the shop, I knew what customers were looking for and what their expectations were.”

Even so, he had plenty to learn about running a shop.

“I still had to learn how to manage people,” he says. “And I needed to know much more about logistics and scheduling.”He quickly learned that managing a shop can be a challenge. David started his career in the shop, serving as a shop manager for a truck equipment distributor in Chattanooga. He knew it can be tough.“The shop is a real proving ground,” David says. “It is easy for technicians to second-guess the manager’s decisions—especially when the manager is the owner’s son. When you are out there, you have to win respect on your own. Your dad can’t do it for you. Buzz worked three years to overcome that. As his dad, it was a difficult thing for me to watch. But he did, and the shop is running well.”

Tale of two brothers

The two brothers brought two different skill sets to Nichols Fleet Equipment.

“Buzz changed things up in the shop,” Nick says. “He is very organized.”

The changes that Buzz brought to the shop are simple, he says.

“I am not following any guidelines that I’ve read or studied. I’ve just tried to create a system for myself and the guys. The idea is to have workflow that works using common-sense procedures.”

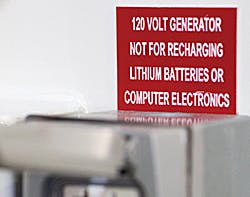

The ideas center on organization, scheduling, and having good people.“Mechanics trucks are the core of our business,” Buzz says. “We want to know the challenges customers have and to address those challenges with the trucks we produce.”“People can buy a mechanics truck anywhere,” Nick adds. “We are always looking for ways to set ourselves apart.”

Why the fish don’t bite

Buzz wants the shop organized and clean.

“For organization, the best idea we have put in place has been a flow chart. It’s a visual board that tracks the status of work in the shop. But the best thing done has been to invest in our staffing. We have always taken advantage of the training schools that our suppliers put on. That’s an investment we are willing to make. Even so, we still need more guys in our shop.”

He also has stressed the importance of preparing for the next job so that technicians can spend more time upfitting and less time chasing down the parts they need. The company’s parts operation includes a couple of people to put kits together by job number as orders come in.Cleanliness is also important.“I’m just nitpicky,” he says, “but when I became shop manager, we got rid of a lot of things we didn’t need—and we cleaned up. Appearance is important. We want customers to look at our shop and realize how much we care.”

Cleanliness is something Nichols Fleet Equipment is willing to pay for.

“We clean up as we go,” Buzz says. “But we pay everyone the last 15 minutes of the day to clean the shop. Some people will say that they work better in a cluttered environment, but I compare it to fishing. You can’t catch fish if you are searching for a lure in your tackle box.”

The approach has helped Nichols Fleet Equipment achieve MVP status with the National Truck Equipment Association.

“The NTEA MVP qualifications should be easy to get,” Buzz says. “They are things distributors already should be doing.”

New approaches to marketing

Nick also has brought change to the company since trading his teaching career for a job with Nichols Fleet Equipment in 2011. They include a new website and an active role on social media.

“Nick brought new things to table,” David Nichols says. “He agreed to join us on one condition—that I would let him set up a Facebook page.”

“This is a visual industry,” Nick explains. “It’s a good way to display the custom work that we do. It’s all about building a brand.”

“Some of what Nick does is like speaking a foreign language to me,” David says. “Nick and Buzz have brought new technology to the company. Web is proving itself, and having a younger generation get involved with the company has made that happen.”

25th anniversary

Vivienne Nichols’ health put a dark cloud over what had been a very good year at Nichols Fleet Equipment. Business was brisk, and the company was celebrating its 25th year in 2016.

David Nichols started the company after working for two other truck equipment distributors. He started his career in the shop, but it was always his goal to get into sales.

“I like people,” he says. “And I like figuring out ways to help them. Demonstrating a mechanics truck and showing how we can make a customer’s job easier is something I enjoy. With Buzz and Nick on board, I’m able to devote more time to those things.”

Meanwhile, Vivienne Nichols is doing well. The type of brain aneurism that she suffered is fatal in more than half of the cases and produces permanent, catastrophic damage to approximately 46%. Only 2% survive without debilitating, permanent damage.

“One of the nurses told me that she had seen plenty of these cases over the course of her career,” David Nichols says. “Vivienne was the first survivor who was capable of talking with her. It’s a miracle that Vivienne is here, and we are very grateful.” ♦

For more information on Nichols Fleet Equipment

check out nicholsfleet.com.