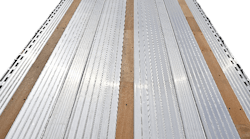

The new Hardox 500 Tuf, officially introduced at the Oil Sands Trade Show this week, has been designed exceptional strength, hardness and toughness in one and the same wear plate. It combines the best properties from Hardox 450 and Hardox 500, and is built for working conditions such as loading and unloading of heavy and sharp rocks in quarries and mines.

Hardox 500 Tuf is tough enough to perform as a structural material in heavy-duty tipper bodies and buckets. Its performance is also proven in cold climates and freezing conditions, according to steel maker SSAB.

Superior wear and dent resistance allow for increased service life and the ability to withstand heavy impact:

- 85-100% longer estimated service life compared to Hardox 400

- Guaranteed impact energy of 20 ft-lb at -4°F (27 J at -20°C)

- Narrow Brinell hardness window of 475-505 HBW

- Highly dent and crack resistant when hit by sharp and heavy objects

*SSAB’s WearCalc and TippCalc calculations based on sliding wear with granite