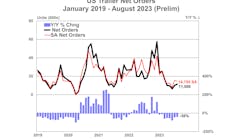

TRAILER MANUFACTURERS have been posting some solid numbers in recent months, but nothing like the 215% increase that ACT Research reported for the month of November.

According to the Columbus, Indiana, transportation research specialist, trailer manufacturers are enjoying sales figures that they have not seen in quite some time. And at least at this point, the supply chain and the manufacturers are handling it.

Net orders of commercial trailers rose to 21,314 in November, up 23% from October. November's results are even more striking in view of the fact that October's performance was the strongest month in over two years. The orders placed in November represent a 215% increase over November 2009, according to ACT Research.

Based on ACT Research numbers, the results in November were no fluke. In the latest release of its State of the Industry: U.S. Trailers, ACT noted the surge has been led by a strong rebound in dry van trailers, the largest segment of the commercial trailer fleet. Over the last three months, net orders for the dry van segment are up 217% compared with the same three months in 2009. On a year-to-date basis, all eight trailer types are up from 2009, although grain trailers and platform (flatbeds) are up only modestly.

The orders come on the heels of a significant upswing in trailer production. Trailer manufacturers report that backlogs are beginning to stretch, especially among dry-freight van manufacturers.

For Hyundai Translead, backlogs are better than they have been in three years, this in spite of major moves that the company has made to meet the demands of the upswing.

Hyundai has added one full production line to its plant in Tijuana, Mexico, and is operating two shifts on three of its production lines.

“It was surprising how fast things turned around,” says Glenn Harney, president.

“We are backlogged through June,” says Mark Roush, director of engineering for Vanguard National Trailer Corporation.

Even specialty van manufacturers such as Kentucky Trailer, noted particularly for its line of moving vans, are experiencing sharp increases in demand, with backlogs to the beginning of the second quarter.

“Business is definitely on the upswing,” says Gary Smith, president. “It's up substantially — roughly 60%. The percentage of increase is eye-popping, but it's because we are coming off a low base.”

Keeping up with demand

The uptick in demand was a pleasant surprise for an industry that had suffered its worst downturn in a generation. Some in the industry had speculated that a quick turnaround in trailer demand would put significant pressure on the supply chain. Because suppliers had dialed back production due to multiple years of declining shipments of truck trailers, the pipeline had pretty much dried up. But with the exception of tires, trailer manufacturers so far are voicing few complaints about the availability of the materials and components required to produce their products.

“We had some supply and lead-time issues when things picked up so quickly,” says Chris Hammond with Great Dane Trailers. “We had to work through those, but we are in a pretty good position right now. There are a lot of dry-freight vans out there that are really long in the tooth, and fleets need to replace them. But at least at this point, things are close to ideal. Demand is continuing to grow, but at a rate that we have been able to handle.

At Great Dane, as has been the case with other trailer manufacturers, explosive growth has occurred in their dry-freight business. But other types of trailers are growing, too.

“We had a good year last year with our reefer trailers, but we believe 2011 will be even better. We are optimistic about the long-term future, which is why we will have a new plant that will come onstream next year.”

Well within capacity

In spite of the upswing, trailer manufacturers are producing well within the industry's overall capacity.

“Yes, orders are up, and build rates are up,” says Kenny Vieth, president of ACT Research. “But trailer production is still well below the rate required just to replace the trailers that are being retired. We still have the capacity to meet current demand, but that could change as we move through this year.”

Roush confirms that statement.

“Demand is increasing exponentially,” he says. “Things started picking up for us slowly. We saw an increase in quotes as far back as the fourth quarter of 2009, and we began to gradually build more in the early part of 2010. Business increased gradually early in 2010, but we are really seeing growth now.”

Vanguard reports running at capacity and hopes to be able to increase capacity by making changes to the production line. The company is only running one line and one shift to produce its dry-freight vans, and management is convinced that the changes it will make to the line will reduce cycle time.

Kentucky is doing much the same thing.

“We are gearing up,” Smith says. “We have added back the positions we were forced to eliminate during the downturn.”

Keeping the pipeline flowing

One trailer manufacturer expressed concern that the demand for trailers could lead to shortages of some component parts — particularly suspensions. However, that does not appear to be the case, at least for foreseeable future.

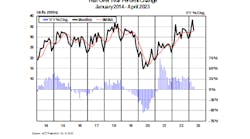

“The first couple of months of 2010 were dead,” says Anita Hain, commodity manager for SAF Holland. “Then the floodgates opened. We really had to ramp up production.”

Ken Griswold, director of marketing services for SAF Holland's operations in North and South America, says demand for van trailers hit first and hardest, but platforms followed a quarter later.

Hain said the key to avoiding shortages is communication up and down the supply chain.

“Our department works closely with our sales team,” she says. “We hold frequent conference calls with our customers and suppliers, so we were able to act quickly to apprise our suppliers of our upcoming needs. We want to be able to walk in lockstep with one another.”

Hain attributes a long-term contract with its steel supplier for a predictable source for steel.

“We have an excellent relationship,” she says. “We communicate daily, and we share the best information we have regarding the market.”

Increased prices

With changing demand comes changing prices in raw materials, components, and ultimately in trailers.

“Aluminum ingot has sold for 70 cents to $1.20,” Bud Hughes, president of Travis Body &Trailer, said as 2010 drew to a close. “Right now we are paying $1.17 a pound. Sooner or later, these price increases will affect the price of finished goods.”

Steel prices have risen as well, but the situation at Vanguard is different from that of most manufacturers. A subsidiary of CIMC, Vanguard gets steel directly from its Chinese parent company.

“We are seeing aluminum going up some in price,” Roush says. “But the steel market in China is not the same as it is here. China does not seem to be feeling the increase in steel prices as much as we are.”

Buying strategically

Raw materials and component parts generally have been available as demand for trailers has jumped. Tires seem to be the one exception.

“We can't get our standard tire brand,” one trailer manufacturer complained. “We have had to mount whatever brand we can locate.”

Vanguard is attacking the challenge in a big way.

“Tires have been the only product we have had difficulty obtaining,” Roush says. “So we are buying strategically, ordering far more tires than we normally would. Tire storage is now a challenge. We are constructing a new building just to house tires.”

Vanguard also is expanding the types of products it manufactures. The company started as a dry-freight manufacturer and began assembling refrigerated vans in late 2009 (see story, December 2009 TBB). Other products are being developed, Roush says.

Looking ahead

Some manufacturers are concerned about shortages later this year — something that was almost unthinkable until recently.

“We are already seeing some pockets in the supply chain were deliveries are stretching out, especially with tires,” Smith says. “Our suppliers are companies like us — they had to scale back, too. And now they are going to have to ramp up.”

Smith says Kentucky is wary of shortages long term.

“We must be on our game when quoting deliveries,” he says. “We want to be certain that we will be able to deliver trailers when we say that we will.”

In spite of the severity of the downturn, Vieth believes the supply chain is still capable of delivering — at least in the near- and mid-term.

“We are forecasting that manufacturers will produce 190,000-195,000 trailers in the United States this year,” he says. “Yes, the downturn has cost some capacity, but this year will be a far cry from what the industry has produced in previous years.”

Analysts predicted that 2010 would be a pivotal year.

“An appropriate description of 2010 trailer net orders would be ‘in like a lamb, out like a lion’,” Vieth says.

The question now is what type of year 2011 will be.

“We forecast based on multiple sources,” Griswold says. “We know that substantial gains are expected this year. The big question is when and how it will occur.”